The Bounty of Bacillus - The Beauty of On-Farm Brewing

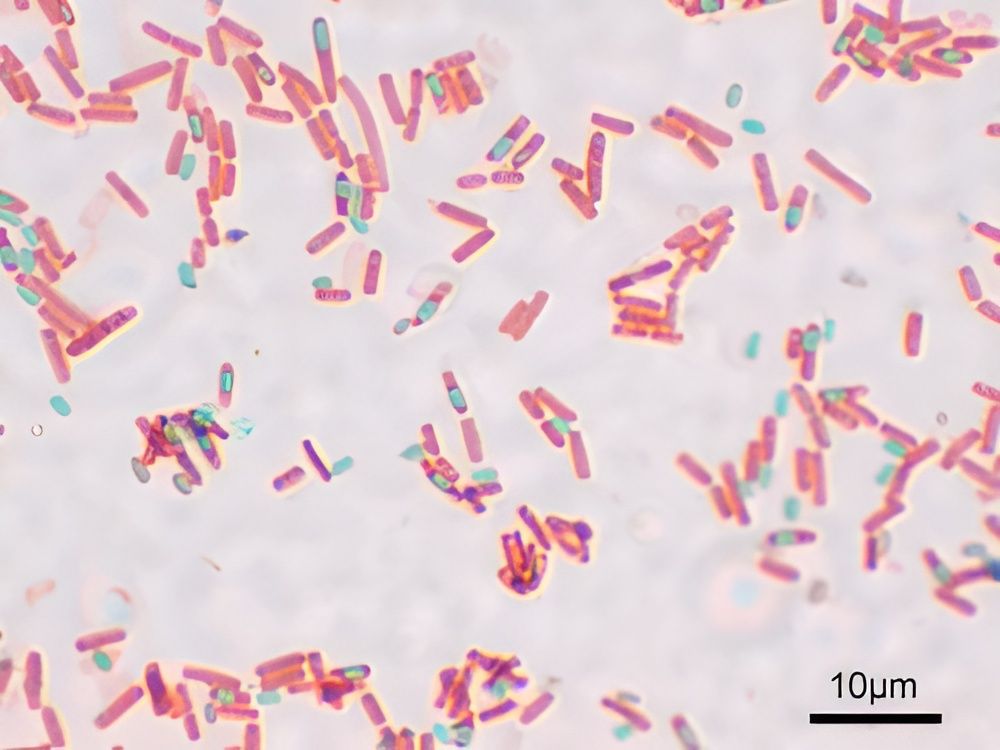

Plant growth-promoting bacteria (PGPB) are becoming integral tools in a more holistic farming model. Here, we are seeking to solve problems and stimulate growth with less chemical dependence. There are a variety of proven performers in this space, but the most productive are those from the spore-forming Bacillus family. Key players from this family can be multiplied on the farm to provide multiple benefits. In this article, we will explore the most researched and accomplished of this group, and I will provide some tips on how we can use them productively.

The best-performing Bacillus problem solvers include Bacillus subtilis, Bacillus amyloliquefaciens, Bacillus licheniformis, Bacillus pumilus, and Bacillus megaterium. I strongly suggest that you search online for the respective benefits of any or all of this quintet to better understand their tremendous potential. It's fascinating to imagine that these strange-sounding bacteria could become household names on the farm in the not too distant future. I often pose a question to my seminar attendees: are any of them familiar with these names? Typically, over 50% raise their hands.

The grim reality is that farming is set to become more difficult amidst the myriad challenges of climate extremes. We need all the help we can muster, and these super-resilient bacteria are tailor-made for the task.

They represent the most robust of beneficial soil life. They can cope with salty or dry soils, wet or overheated scenarios, and they are also more chemical-resistant than most. All five of these species can fix nitrogen and solubilise phosphate, and and they are all major producers of an enzyme called chitinase, which can have both fungicidal and insecticidal benefits. This enzyme digests chitin, which is found in the outer walls of both fungal pathogens and insect pests. Chitin also comprises the inner wall of the gut lining of caterpillars, so there is also potential larvicidal benefit.

This group can also provide some unique individual offerings. Let's look at some of these, starting with Bacillus subtilis.

The Bacillus Immune Elicitor

Bacillus subtilis is a multifunction marvel, so it's unsurprising that it has become the world's best-selling bio-fertiliser. This remarkably versatile organism offers direct and indirect benefits to your crop. The direct, protective capacity relates to the synthesis of a suite of secondary metabolites, hormones, cell wall-degrading enzymes, and antioxidants that support the plant to ward off pathogen attack. The secondary mechanism involves the generation of a powerful immune response called Induced Systemic Resistance (ISR) and the associated stimulation of plant growth and yield. I have mentioned many times that immune elicitation always equates to yield increases.

Bacillus subtilis can also solubilise soil phosphorus (P) and enhance nitrogen fixation, as mentioned, and it produces siderophores that promote its growth and suppress the growth of pathogens. Bacillus subtilis enhances stress tolerance in plant hosts by inducing the expression of stress-response genes, phytohormones, and stress-related metabolites. Impressively, this organism is so hardy it can actually be added at the start of composting and still be present in the end compost. That is highly unusual because the heating stage (the thermophilic phase) of composting involves a unique group of trailblazers that can handle the heat, and then the more common soil species kick in during the latter stages.

Part of this resilience is due to the organism's ability to form spores, enabling it to momentarily pause when conditions become challenging and resume activity when conditions improve. Bacillus subtilis showcases extraordinary tolerance to abiotic stresses. It can endure droughts, heatwaves, wet spells, UV radiation, and chemical pollutants more effectively than most of its counterparts. Even in soils with limited nutrients, it can outcompete other microbes while still performing its numerous tasks. Its ability to form protective biofilms further enhances its resilience. This attribute also allows it to tolerate extreme soil pH levels that might inhibit other microbes. We will delve deeper into the topic of biofilms later.

Now, let's take a more in-depth look at Bacillus licheniformis.

Seed Treating with the Drought Bug

Bacillus licheniformis has been demonstrated to significantly enhance water use efficiency, even when solely used as a seed treatment in dryland broadacre. This organism is a facultative anaerobic bacterium, capable of both anaerobic respiration and fermentative growth (Clements et al. 2002). This means it can survive in both the presence and absence of oxygen. Such a capability allows this beneficial bacterium to flourish in the rhizosphere, even when oxygen levels are reduced due to drought, flooding, or high-magnesium soils.

An important component of the increased drought resilience associated with both Bacillus subtilis and Bacillus licheniformis relates to their production of substances called biosurfactants. Bacillus subtilis produces a much-researched substance called "surfactin," while B. licheniformis produces an equally exciting biosurfactant called "lichenysin." Both of these natural surfactants are of particular benefit, relative to water use efficiency because they reduce soil surface tension, making it easier for water to penetrate and disperse throughout the soil. This improves soil structure and helps prevent water runoff, while enhancing soil moisture retention.

However, the benefits of this surfactant gift don't stop there. Biosurfactants can solubilize nutrients and minerals, making them more available to plants. This nutrient availability has a positive effect on the health of both plants and microbes. Moreover, these biosurfactants have been shown to stimulate and enhance the organisms responsible for biodegradation of pollutants and contaminants in your soil. Bacillus licheniformis can be used as a detox inoculum, and there are some good studies to support this potential, including those demonstrating bioremediation of heavy oil contamination and nickel toxicity.

We are currently losing 7 to 12 tonnes of topsoil per hectare per year, and this is increasing with climate extremes. At that rate, it has been estimated that we have a little over 50 years before our precious topsoil disappears. It's a huge issue that requires a much stronger focus. Biosurfactants can reduce soil erosion by improving soil structure and water infiltration. This improved soil structure can help create a disease-suppressive soil while providing more uptake of nutrients and water for greater drought resilience.

Like the others of this trio, this Bacillus strain has considerable biocontrol potential. In fact, a study entitled "Biocontrol Traits of Bacillus licheniformis" concluded that this organism could reduce and inhibit the mycelium growth of diverse plant pathogens, via a suite of secondary metabolites, including chitinase, to dissolve the chitin-based cell walls of insects and disease organisms.

I guess you are starting to recognize that the introduction of beneficial Bacillus species into your soil might be productive. Now, let's look at the poster boy of this potential. Bacillus amyloliquefaciens has become a huge focus of research and excitement after it was identified as a standalone species, rather than a form of Bacillus subtilis.

Bacillus Biocontrol

The growing enthusiasm for Bacillus amyloliquefaciens largely revolves around its role in disease management. There are many studies involving a multitude of diseases. One such study, a 2018 paper titled "The Multi-Faceted Benefits of Bacillus Amyloliquefaciens..." by K. Elanchezhiyan et al., explored the control of fusarium in tomatoes using this organism. The treatment was found to activate various defence activities, including superoxide dismutase, catalase, peroxidase, and phenolic acids. The researchers also highlighted notable plant growth promotion and yield increases. In their experiment, the application rates that proved effective included dipping seedlings in a solution containing one teaspoon of inoculum per litre and applying 500 grams per hectare as a foliar application.

Other research on Bacillus amyloliquefaciens (BAA) has similarly showcased the yield-boosting potential of this inoculum. In one study involving tomatoes treated with BAA, the fertiliser requirements decreased by 25%, maintaining equivalent yields. Another study, focused on a corn crop in low-phosphate soils, revealed that the BAA treatment increased both phosphate availability and the associated yield.

There is also potential to integrate this organism with conventional fungicide programs as the Bacillus organisms are not negatively impacted by fungicides. A 2008 study on the control of Sclerotinia sclerotiorum in canola, published in the journal "Crop Protection," validated this integrative strategy. H. Zhang et al. discovered that using Bacillus amyloliquefaciens alongside reduced fungicide applications successfully curbed the disease. Remarkably, all five of the Bacillus species under discussion resist the lethal effects of fungicides. This suggests a promising avenue for reducing chemical requirements and boosting efficacy with an integrated approach.

There is also considerable interest in this organism's potential for nematode control, with studies indicating reductions in eggs, worms, and root galls.

Next, we will look at the phosphate-solubilising specialist Bacillus megaterium.

Unlocking Frozen Reserves with Bacillus Megaterium

It is commonly acknowledged that your crop receives just 27% of water-soluble P before it locks up in the soil and becomes part of a frozen reserve estimated to exceed 10 billion dollars. It's disconcerting to realise such dramatic inefficiency, where you benefit from just slightly over a quarter of your P investment. However, the good news is that you haven't lost it. If you pay a little extra and test your total phosphate reserves, you will find that this frozen investment remains in your soil, sometimes in many hundreds of ppm. Depending on the phosphate fertilisation history of your soil, you might have sufficient phosphate in reserve to support numerous crop cycles. The key question becomes, "How can I tap into my 'frozen' reserves and reduce my escalating fertiliser costs?""

There are several P solubilising strategies to consider. One approach is the use of legumes, whose acidic root exudates can sever the bond between immobile phosphorus and calcium (or phosphorus and iron in red soils). However, for these P solubilisers to be effective, they must be functioning legumes, otherwise they are nothing more than a passenger in the paddock. But what defines a 'functioning' legume, you might wonder. Simply put, these plants must contain the red pigment known as leghaemoglobin within their nodules. Without it, they can't release an acidic exudate, making them ineffective at P solubilisation.

Another particularly productive technique to access your frozen lode involves the use of P-solubilizing biology. The two most researched options here include Bacillus megaterium and mycorrhizal fungi (AMF). Let's look at the bacterial option more closely.

It's interesting to understand exactly how these creatures release your locked-up phosphate reserves. Bacillus megaterium releases phosphatase enzymes that catalyse the release of phosphate from organic matter. They can also be used in conjunction with molasses to increase the plant-available P component of natural rock phosphate and guano.

Similar to legumes, these bacteria can produce organic acids like citric acid and gluconic acid. These acids can help dissociate the triply negative-charged phosphate from the doubly positive-charged calcium, resulting in water-soluble phosphate. This process is a more gentle version of the acids like phosphoric acid and sulfuric acid that are used to create water-soluble P from rock phosphate (in the case of DAP/MAP and superphosphate).

Bacillus megaterium also produces powerful iron-chelating substances called siderophores. These can effectively increase phosphate availability because they reduce the formation of insoluble iron phosphate.

Additionally, these Bacillus strains secrete sugars termed exopolysaccharides (EPS) that exhibit strong chelating capabilities with calcium and magnesium. When these doubly positive-charged cations are bound, they cannot attach to phosphorus. This means more phosphate remains available for crop uptake.

Phosphate is a non-renewable resource, and we are very close to a phenomenon called "peak phosphorus." Historically, when a non-renewable resource "peaks," we see ongoing price increases until the resource is exhausted. Hence, we can expect to see the rise and rise of phosphate prices if this mineral follows this trend. Increasing P efficiency and accessing our reserves becomes increasingly important in a "peak P" future.

Let's now have a more in-depth look at the last of the 5th species of this super-productive workforce. Let's consider the role of Bacillus pumilis.

Bacillus Pumilis - The Benefits of Biofilm

Bacillus pumilis, the last of our illustrious quintet, is a nutrient cycler that breaks down organic matter into humus, releasing phosphorous and nitrogen. Like the other Bacillus strains, it also solubilizes frozen phosphate through the release of acids and phosphatases. It also releases growth-promoting biochemicals, helps control pathogens, and interestingly, it is important in the establishment of mycorrhizal fungi. In a study published in "Tree Physiology" in 2022, Ya-hui Wang et al. demonstrated that pine seedlings inoculated with Bacillus pumilis enjoyed 158% better mycorrhizal colonization.

However, perhaps the most significant contribution of Bacillus pumilis lies in its capacity to produce substantial amounts of biofilm. All five of the Bacillus strains we've discussed possess this capacity, but Bacillus pumilis is the recongised master. So, what's the significance of biofilms? What are they, and how can they benefit our farms?

Biofilms are produced by microorganisms using the exopolysaccharides (EPS) mentioned earlier, combined with proteins and fats, to form a sticky, protective matrix in which diverse microbial communities can coexist. These films offer various benefits for their inhabitants. They provide protection and shelter, shielding them from harsh environmental conditions like UV radiation and chemical stress. Biofilms can foster micro-environments with distinct nutrient gradients, enabling different organisms to access specific resources. They also help bind soil particles together, promoting soil aggregation and stability. This enhanced soil structure boosts water infiltration, root penetration, and aeration, potentially helping reduce the present losses of 7 to 12 tonnes of topsoil per hectare annually.

Biofilms, housing disease-suppressive microbes, can form a protective barrier around plant roots, preventing damage by plant pathogens. These biofilms can also become nutrient traps, helping to retain key nutrients in the root zone.

Perhaps one of the most important characteristics of biofilms relates to drought resistance. The extracellular matrix can retain water and minimise water runoff, an aspect that is particularly crucial given the hot, dry summer anticipated in Australia. Biofilms can harbour growth stimulants and plant growth hormones produced by Bacillus strains and other organisms. Finally, symbiotic relationships can flourish within these sheltered communities, where cooperation creates a greater outcome. Here, the whole is definitely greater than the sum of the parts.

The ability of Bacillus pumilis to generate vast amounts of biofilm is a major benefit. However, as we've learned, this microorganism, along with the other four Bacillus strains discussed, can also fix nitrogen, solubilise phosphate, and produce chitinase for enhanced pest management.

Now, let's look at how we can utilise these organisms to achieve some desirable outcomes on the farm.

Five-in-One Micro-Force - Brew Your Own Beneficials

Here's the good news: We have a product named Micro-Force™ that contains freeze-dried forms of all five of the organisms we've discussed. These "spores in suspension" need to be brewed for 24 hours with oxygen and a food source. This on-farm, living fertiliser produced is incredibly cost-effective. In fact, the final brew costs less than 20 cents per litre!

So, how do you brew this blend on the farm? Well, you'll require an aerobic brewing tank. It doesn't have to break the bank, but the crucial requirement is the continuous delivery of thousands of minute bubbles throughout the 24-hour brewing process.

You can use a 20-litre bucket, a 200-litre drum, or a 1000-litre shuttle. If you're in broadacre farming, the 2500-litre option might be worth considering. NTS offers a 20-litre home garden brewer, and we also supply submersible pumps with venturis for the 200 and 1000-litre options, as well as a kit for the 2500-litre tank. If you visit our website, you'll also find the BrewStar 200™ bubbler option, which uses an external air pump to produce billions of tiny bubbles. This kit includes a 100-micron "tea bag", a tank thermometer, the pump, the bubbler kit, and the brewing tank. Additionally, it can serve as an anaerobic brewing station because it comes with a screw-on lid that can be fitted with a one-way valve.

The brewing process simply involves adding clean water, food, and oxygen for 24 hours, after which you have your homemade living fertiliser.

We have developed a specialised food for brewing Micro-Force™ called Liquid Microbe Food™ (LMF), which is used at 1 litre per 100 litres. However, there is also a highly effective DIY option that I've highlighted in my podcast. I'll detail that recipe shortly, but first, let's consider some other brewing aspects, including:

- The tank and the water within must be sterilised prior to use. You can use pool chlorine as per the label's recommendations, but it's essential to bubble off the chlorine gas before introducing the microbes and their food source. This process may take up to 2 hours, and your sense of smell will be your guide. There should be no trace of a chlorine odour emanating from the bubbling water before it is deemed safe to add the microbes. To be certain, I often let it bubble overnight.

- The ideal water temperature for Bacillus brews is between 30 and 33 degrees Celsius. During colder periods, you have the option to use a tank heater or simply add hot water to achieve this optimal temperature. Once the organisms begin their rapid multiplication, they will typically sustain and even produce some heat on their own.

- The best pH for brewing Bacillus is a neutral 7. Depending on your starting conditions, you may need to adjust the pH using citric acid or potassium hydroxide.

Here is the recipe for 200 litres of brewed Micro-Force™, but you can divide these ingredients by 10 for a 20-litre brewer or multiply by 5 for a 1000-litre brew:

200-Litre Micro-Force Recipe with DIY Food Alternative

- Fill your brewing tank with 180 litres of water and adjust temperature and pH as described.

- Add chlorine according to label rates and bubble the water until there is zero chlorine smell.

- Now add the following food recipe:

A) 4 litres of Molasses

B) 100 grams of magnesium sulfate

C) 1 kg of urea

D) 80 grams of sea salt (pool salt is sufficient)

E) 80 grams of NTS Fulvic Acid Powder™

F) 400 mL of NTS Amino Max™, liquid amino acid concentrate - When this food mixture is fully dissolved, add your Micro-Force™ freeze-dried Bacillus, at the rate of 100 grams per 200 litres.

- Brew for 24 hours, and your inoculum is ready to use.

On my farms, we typically apply the end brew at 20 litres per hectare, but that is because we have not optimised numbers with a tank heater. If you multiply the organisms according to the above instructions, then they can be used effectively at 10 litres per hectare. That equates to a cost of just $2 per hectare. Do you understand why I get so excited about microbe brewing?

In conclusion, we're currently facing a highly challenging situation. Commodity prices have often plummeted, while production costs have surged. Consider ginger, macadamia, vegetables, avocados, cattle, and sheep. The on-farm production of living fertilisers provides a cost-effective alternative to escalating fertiliser and chemical expenses. Moreover, it's not only great fun but also immensely rewarding. I hope this inspires you to try out brewed microbes on your land. Should you have any questions, don't hesitate to reach out to the NTS agronomy team on +61 7 5472 9900 or send a message via our contact form.

Happy brewing!